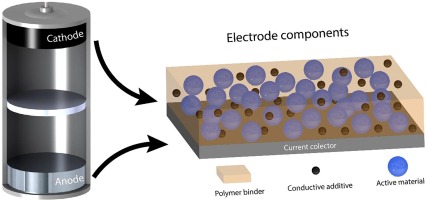

While little success has been obtained over the past few years in attempts to increase the capacity of Li-ion batteries, significant improvement in the power density has been achieved, opening the route to new applications, from hybrid electric vehicles to high-power electronics and regulation of the intermittency problem of electric energy supply on smart grids. This success has been achieved not only by decreasing the size of the active particles of the electrodes to few tens of nanometers, but also by surface modification and the synthesis of new multi-composite particles. It is the aim of this work to review the different approaches that have been successful to obtain Li-ion batteries with improved high-rate performance and to discuss how these results prefigure further improvement in the near future.

the first Li-ion battery equipped with a LiCoO2 cathode element in 1990 [1]. This battery is still used for portable applications, but fails to be used for applications demanding more power, such as electric and hybrid vehicles, mainly for safety reasons [2,3]. Since then, other cathode elements have been proposed; they can be divided into three different families. One is the family of lamellar compounds to which LiCoO2 belongs, obtained by the multi-ion substitution of Co. The archetype of this family is LiNi1/3Mn1/3Co1/3O2 (LNMC) first introduced by Ohzuku’s group in 2001 as a candidate cathode material [4,5]. The role of Mn is to order the Li; Ni is the electrochemically active element. Co is still needed to avoid the antisite defect corresponding to Ni2+ on the Li+ site [6] facilitated by the fact that Li+ and Ni2+ ions have almost the same ionic radius; antisite defects damage the electrochemical properties where the defect concentration exceeds 2 at. % [7].

The second family is the olivine group, the archetype of which is LiFePO4 (LFP) [8]. However, the low intrinsic electronic conductivity postponed its use, until the problem was solved by coating the particles with conductive carbon [9], which has been a remarkably successful surface modification. A few additional years were required before the material could be freed from any impurity [10]. Since then, the material has been extensively studied. The physical and electrochemical properties as well as the surface and size effects have been reviewed recently [11,12,13,14]. For the purpose of the present work, we can summarize the state-of-the-art by saying that there are now different synthesis routes at the industrial scale that make possible the preparation of LiFePO4 particles of different sizes, from submicron to the nano-range depending on the use that is targeted, that are free of any impurity. We only redirect the reader to these prior reviews for more information